Visual Inspections are still as important as ever!

February 22, 2017

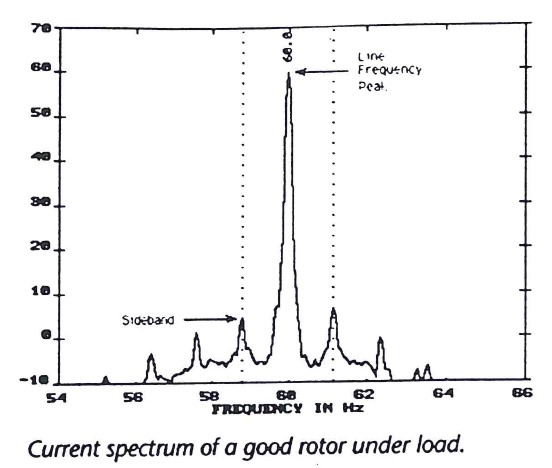

In the world of technology, more specifically maintenance technology, there are so many different tools we are using to make decisions. We use vibration analysis, ultrasonic analysis, motor current analysis, thermography, and so many other technologies that many times the most simple and cost-affordable technology is sometimes forgotten: YOUR EYES! Visual inspections can tell you …