Common Preventable Electric Motor Failures: Bearings

January 4, 2018

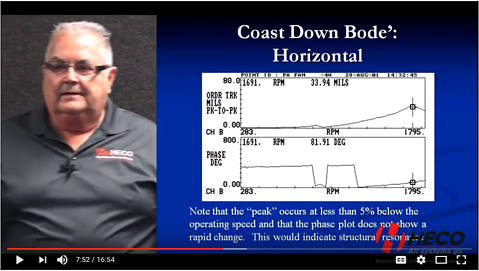

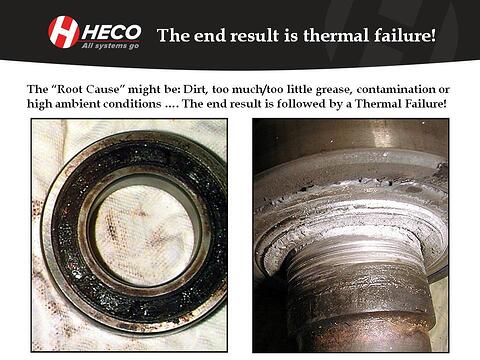

The below video is a 15 minute segment of an hour long presentation given by Todd Hatfield of HECO at the 2017 Reliability, Process, and Maintenance (RPM) Symposium. This presentation discusses common preventable causes of electric motor failures. This section of the presentation discusses bearing related failures as bearings account for about 51% of all …