Common Preventable Electric Motor Failures: Bearings - HECO

January 4, 2018

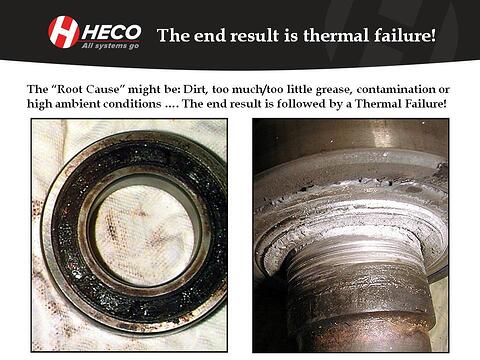

The below video is a 15 minute segment of an hour long presentation given by Todd Hatfield of HECO at the 2017 Reliability, Process, and Maintenance (RPM) Symposium. This presentation discusses common preventable causes of electric motor failures. This section of the presentation discusses bearing related failures as bearings account for about 51% of all electric motor failures.

This presentation discusses bearing failures related to:

- Insufficient lubrication

- Too much lubrication

- Mixing incompatible lubricants

- Contamination

- Electrical damage or fluting

Besides showing the issues and type of failures, this presentation discusses what you may be able to do to help prevent these failures from occurring.

Posted in Equipment Management, Predictive