Case Study 5500HP, 13,200v, Synchronous Motor: (Part 3) Electrical & Mechanical Redesign Engineering - HECO

July 15, 2019

In part 3 of this case study, Todd Hatfield will be discussing how HECO re-engineered the electrical and mechanical design of the surplus motor to match the 5500HP, 13,200v original motor.

This 13 minute presentation will go over:

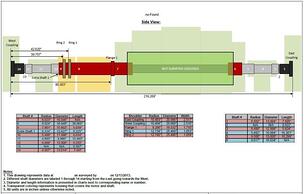

- On-site laser measurements using FARO technology

- Determining challenges such as

- How the spare motor would fit into the existing pit

- Configuring an adapter base to fit the new motor

- Creating an identical shaft that could fit into the spare motor

- Duplicating couplings and slip rings

- An Engineering Design Assessment confirming that the spare motor could be redesigned to 5500HP

- The discovery of a series reactor that would put less stress on the whole system

- A Power & Load study of the original motor and application to better understand the load and amperage variation

- Interpreting the Engineering Design Assessment results

Make sure you are all caught up with the series starting with…

Posted in Field Service, Predictive, Repair