Mechanical Inspection of Electric Motors: What Really Matters?

January 13, 2021

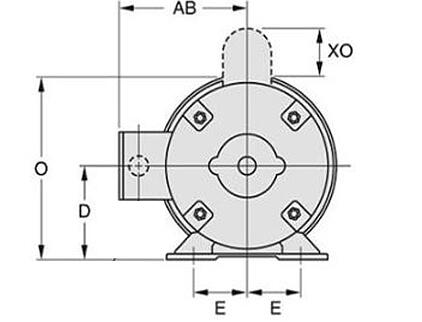

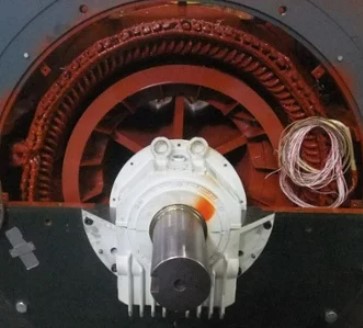

When it comes to inspecting electric motors, it’s not just the electrical components that are important. The mechanical aspects of a motor are extremely important to its performance, which is why mechanical inspection of electric motors is so important. Critical Fits for Electric Motors Electric motor inspection, when done correctly, always includes a mechanical inspection. …