Electric Motor Repair Vs. Replacement Determination

April 11, 2017

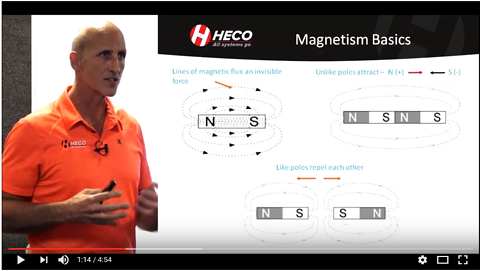

When an electric motor fails, a plant must make decisions in a timely manner, but the decisions made can have a major impact to reliability in the long run. Should you repair the current electric motor or replace it with a new one? This presentation covers some direction to making a plan in order to …