Visual Inspections Can Help Avoid Issues, Unnecessary Maintenance Costs

June 28, 2023

Are you the kind of person that checks your vehicle’s oil level and quality between oil changes or do you just trust that the automotive manufacturer knows when your oil goes from “good” to “get an oil change now!” status?

At HECO, we’re both hyper-aware of the manufacturer specifications and proactive about minding our machines – from our personal daily drivers to the industrial electric motor systems we sell, Field Service, and Repair.

In the world of ever-evolving technology, there are many tools available for maintenance technicians to make decisions including vibration analysis, ultrasonic analysis, motor current analysis, and thermography. While these technologies are extremely valuable for identifying issues before they cause catastrophic problems or for diagnosing the source of poor performance or a breakdown, the simplest and most cost-effective method is our vision!

Performing in-house visual inspections and working with a service partner who helps you understand how a piece of equipment is running, what to watch out for, and how to document findings can save you unnecessary maintenance, Repair, and shutdown costs.

What to Watch For

Does your motor have clogged filters?

Is there an oil leak? Is the oil level high? Is it low?

Is the fan cover plugged? Are cooling fans plugged?

These questions are simple yet telling. Developing a record of these responses and other machine data can help you notice issues in the moment as well as understand the system’s performance and future needs.

Most plants have some form of visual inspection performed by operators and in-house maintenance professionals. These assessments might be performed daily, quarterly, or somewhere in between. Regardless of who is performing the inspection, paying attention to a consistent set of data points and maintaining a regular schedule are the key to success.

Walking around and looking for obvious issues may be helpful, but a trained team member with training, familiarity with the system, and a defined set of criteria will be a lot more successful.

Additional questions to consider during a visual inspection and potential ramifications include:

- Can you see oil in the sight glass? If so, what color is it? Using the wrong oil or oil that is too old can cause your motor to seize up and cause unexpected downtime.

- What condition are the filters in? If dirty or clogged, the motor may be starving for air, causing it to run hot and shortening its life expectancy.

- How does the machine base look? An unsteady or imbalanced base can cause motor vibrations and internal damage.

- Is the exterior of the machine clean? Does there appear to have been water damage? Exposure to environmental elements and debris can wreak havoc on a motor’s internal operations.

- What do you hear during the machine’s operation? Knocking may indicate misalignment while high-pitched sounds could be a sign of electrical issues.

While these questions may seem obvious, a simple observation could save you tens of thousands of dollars. For example, replacing bearings costs approximately $50,000, but, if issues go unnoticed until a rewind is necessary, the cost could be more than $200,000.

The HECO Approach

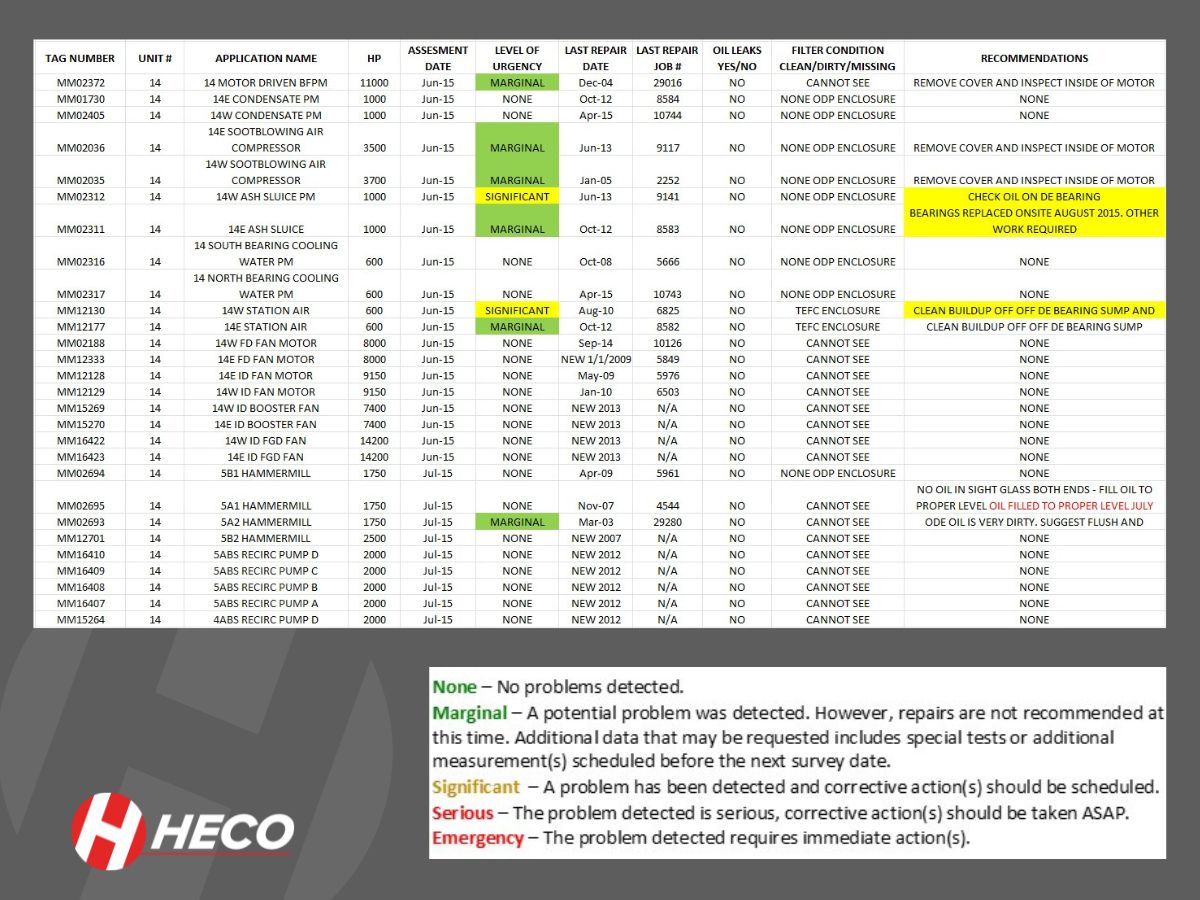

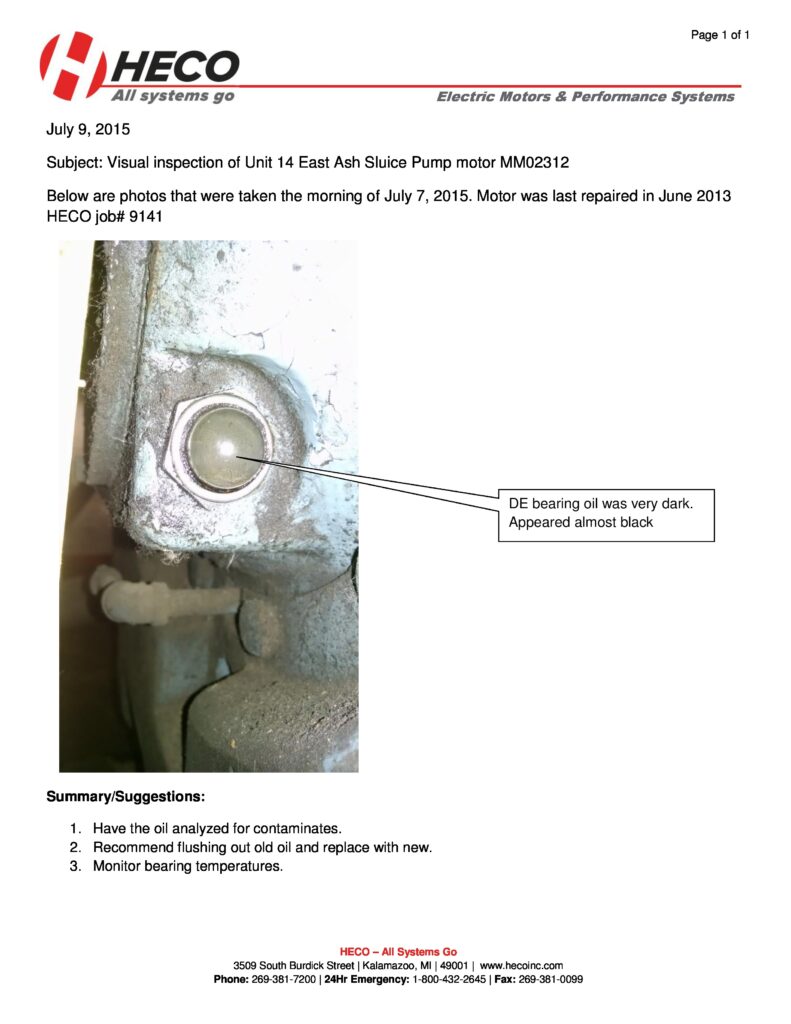

Some of our visual assessment programs mirror a Predictive maintenance route. HECO provides color-coded reports on all items and then a more detailed report with images of any item that displays an anomaly. It’s amazing what simple pictures can do in showing what the issues are.

Here are some examples of the larger report as well as a detailed individual report.

For some larger HECO customers, inventory reports may contain 30-40 motors. Having all of the machine data at a glance helps the company and its scheduler determine which machine to pull next.

Whenever possible, we prefer to talk to the machine’s operator as well. Their impressions, coupled with historical data and observations, can be extremely telling.

All Systems Go

Visual inspections are an old-school yet important method to monitor machines and critical systems in addition to technological advances such as remote monitoring and APOLLO from HECO. Working with a trusted partner to define the parameters of sight-based evaluations is an extremely important part of monitoring systems, avoiding issues, and preventing unnecessary maintenance and spending.

Contact us for assistance in collecting and interpreting your visual inspection data.

Posted in Equipment Management