IIoT vs. PdM (Internet of Things Vs. Predictive Maintenance) - HECO

June 27, 2018

When you start a compare and contrast with Predictive Maintenance and the Internet of Things within the industrial maintenance world; you may have some people scratch their head and say, “are they not the same thing?”. Well, the easy answer is a simple answer of yes and no. Yes, they are both moving towards a new way of understanding maintenance and maintenance needs. No, they are not the same because different tools and technologies are being used to assess equipment and assets.

Break Down of Each:

Predictive Maintenance

Predictive maintenance starts with the understanding that you are using the approach to schedule maintenance during times when it is most cost effective and before the equipment moves into critical periods when it may be prone to critical failures or efficiency losses. Most Maintenance monitoring is being done while the equipment is running during production to help maintain plant production needs. Also, this time is used to start a baseline to establish what normal running conditions for equipment is during production.

Tools being used can differentiate between needs. Hand Held Vibration analyzers, Ultrasound equipment, Infrared Equipment, and oil analysis are used separately or combined to help assess mechanical condition of equipment.

(Industrial) Internet of Things

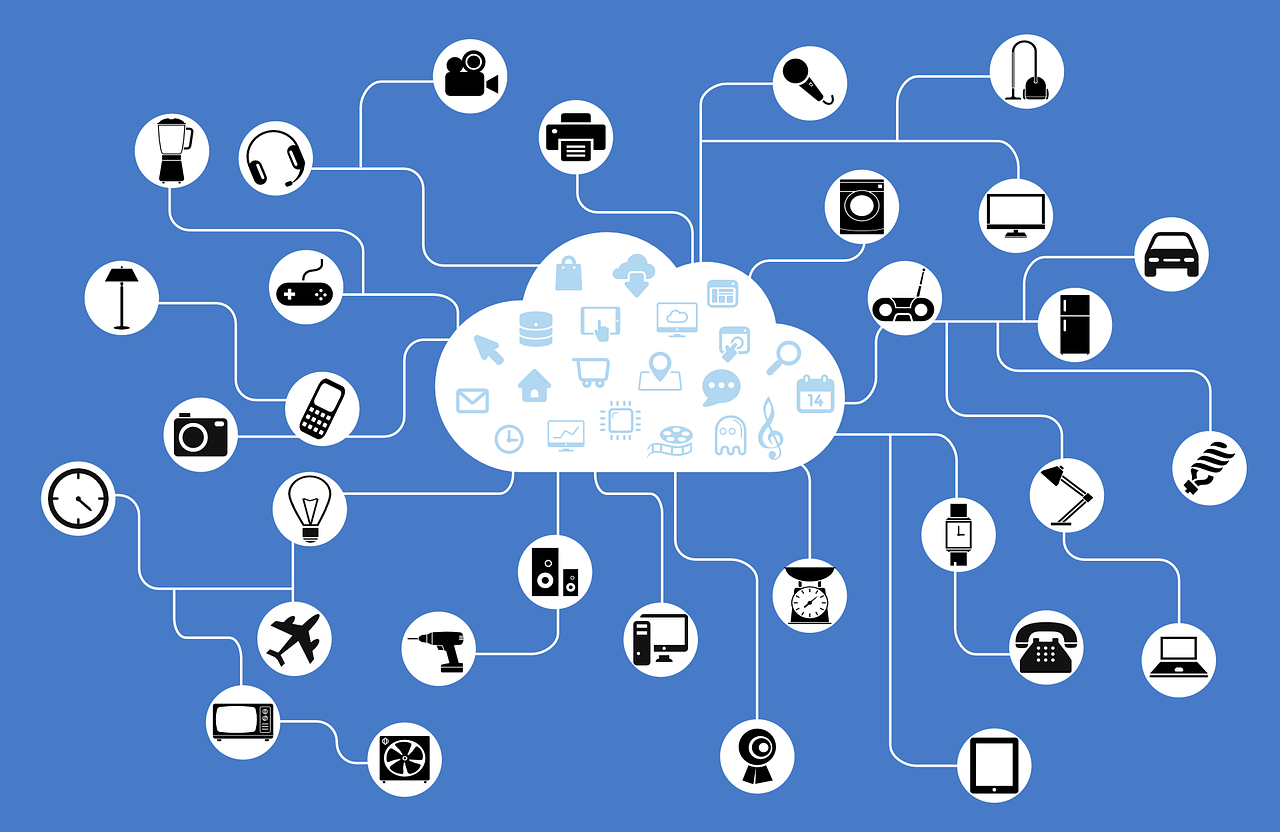

IIoT starts with understanding that you are trying to “understand the machine” and you are using sensors, gauges, and machine to machine communication to collect DATA to pick up problems, inefficiencies, and equipment problems sooner. IoT allows for easier integration of this DATA capture to follow the equipment along its lifecycle regardless of location or re-location of assets. Trending data can be inserted into an asset management software for an “history” of that particular piece of equipment. You can call it an Industrial “medical file” of the equipment.

The equipment is being continuously monitored with sensors and equipment connected to an network for on-site and off-site management. The internet of things is much larger than just Predictive Maintenance – although predictive maintenance is a part of it!

Which is better:

Both are growing in industry: Companies are asking their vendors to help them set up these systems as they transition from Reactive Maintenance (Run to Failure Practice) to the more cost effective way of Scheduling maintenance practices. Maybe sitting down with your staff (reliability, production, maintenance) and a partner who understands and can evaluate your needs will help institute a plan to help you meet your maintenance goals.

Posted in Predictive