How Does an Induction Electric Motor's Rotor Work? - HECO

July 28, 2016

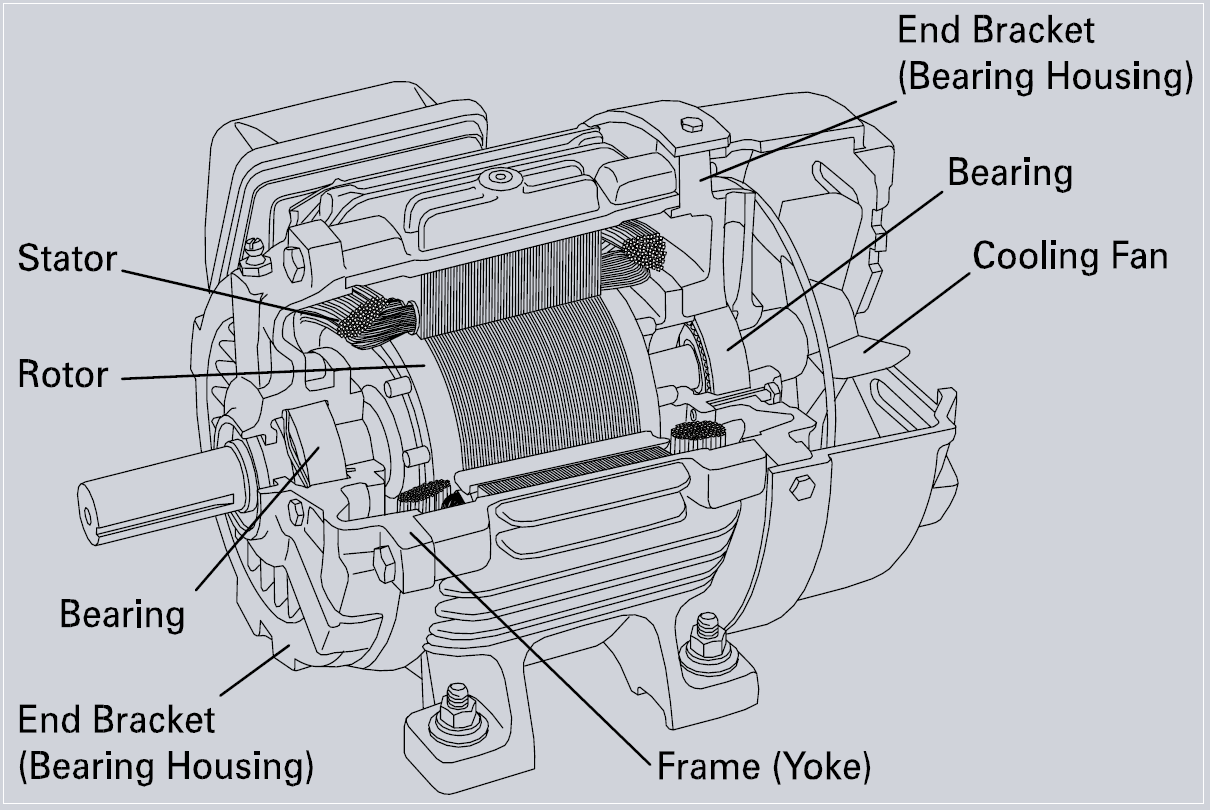

The induction of current flow through an induction electric motor’s rotors bars occurs when current is applied to the stator. This applied current through the stator windings starts the rotation of the stators magnetic field at line frequency.

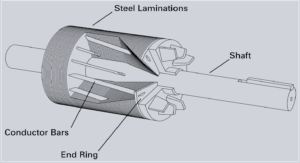

The rotor bars of the stationary rotor are then subjected to the maximum relative motion of the stators magnetic field to the bars. At this point, maximum current is generated along the bars. As the stators north pole rotates pass a rotor bar, current is induced along the rotor bar. At the same instant the stators south pole rotates passed a bar 180° apart and induces current along that bar in the opposite direction. This circular flow of the current along the rotor bars through the shorting rings and around the laminations causes the rotor to become an electro-magnet.

It is at this stationary (locked rotor) starting point that the electromagnetic strength of the rotor is strongest. The electromagnetic rotor will begin to accelerate to synchronous speed or the speed at which the stators magnetic field is rotating. As the rotor increases in speed, the relative motion between the rotor bars and the rotating magnetic field decreases. This results in a decrease in current flow and torque. As the relative motion (rotating force) between the rotor bars and stator magnetic field approaches zero, the current flow along the rotor ceases. The rotors magnetism will cease and the rotor will slow down until the torque generated by the motor equals that of the driven equipment.

If the motors load is increased the motors speed will decrease. Decrease the load and the motor will increase in speed. An induction motor will never reach synchronous speed due to friction and windage losses. The difference between synchronous speed and induction rotor speed is called slip frequency.

Want to know more about your electric motor’s rotor? We have the knowledge and expertise at HECO, All Systems Go.

Posted in Equipment Management