Are Repair and Reliability Enemies?!

November 18, 2021

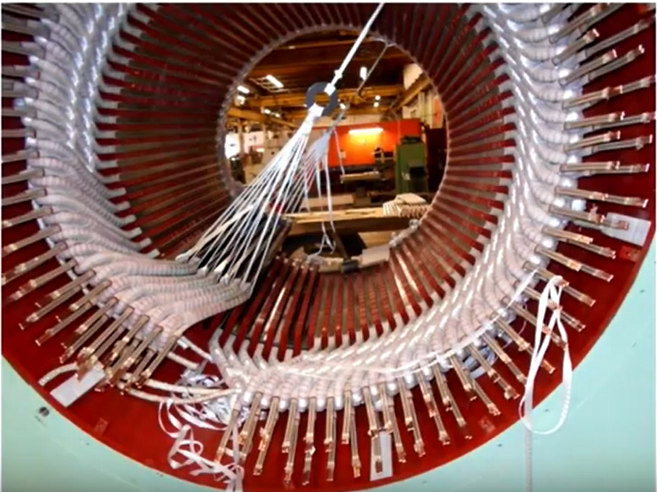

At my core, I am an electric motor guy, more specifically an electric motor repair guy – or at least that’s what I have always thought. I am a fourth-generation family member in the electric motor repair industry. I am the President of a large primarily electric motor company with various divisions including electric motor …