Why Motors Fail: Part 3 – The Top 5 Electrical Failures in AC Motors

July 30, 2025

While mechanical failures often dominate conversations about motor downtime, electrical issues can be just as disruptive.

At HECO, we utilize a proprietary Equipment Management software known as TracRat to track our clients’ motor inventory and collect specifications, repair history, and application and performance data for each unit to enable faster asset replacement, streamline maintenance, and improve reliability through actionable insights.

As discussed in previous posts in this series, Part 1 – The Top 5 Failure Modes for AC and DC Motors and Part 2 – Avoid the Hidden Costs of Misalignment, Lubrication Issues, and Shaft Voltage, we analyzed TracRat data spanning more than 240 client facilities and thousands of motors across all the industries we serve to learn more about motor failure trends and develop solutions.

In this post, we’ll highlight the top five electrical failure modes for AC motors, discuss how each issue presents itself, and describe actions you can take to avoid these motor failures and downtime.

1. Winding Failure Due to Overload: When the Motor Says ‘Enough is Enough’

Overload occurs when a motor operates beyond its designed load capacity. This often stems from misapplication during system design or evolving process demands that outstrip the motor’s capabilities.

Common signs of overload HECO sees include:

- Discolored or burned wires.

- Excessive heat and unusual odors during operation.

- Tripped overload relays.

Prolonged overloading significantly reduces the life of winding insulation. For every 10°C rise in operating temperature over the rated temperature, insulation life decreases by half, increasing the likelihood of motor failure.

Avoid overload-based winding failures by ensuring that motors are appropriately sized for their applications during the design phase and accounting for potential load increases. During regular operation, use overload protection devices to limit stress, and regularly inspect motors to monitor load conditions and prevent overuse.

2. Overheating and Blocked Ventilation: Restricted Airflow Restricts Productivity

Blocked or restricted ventilation is one of the most common contributors to overheating. Dust, debris, and grease buildup can trap heat, leading to insulation damage.

Signs of overheating and blocked ventilation include a motor’s casing feeling excessively hot to the touch, internal components that show discoloration or damage due to heat, and visibly obstructed ventilation pathways.

Resulting damage accelerates the breakdown of insulation, causing electrical shorts, winding failures, and potentially irreversible damage to the motor.

To avoid heat-driven failure:

- Clean ventilation pathways by regularly inspecting and cleaning ventilation grills and motor housing.

- Utilize environmental controls such as installing motors in well-ventilated areas or use cooling systems where ambient temperatures are high.

- Perform routine checks using Predictive maintenance to identify airflow blockages early.

3. Insulation Deterioration and Low Resistance: Aging Infrastructure Invited Issues

Degraded insulation increases the risk of phase-to-phase or phase-to-ground faults, leading to immediate and often catastrophic motor failure.

Insulation shields windings from electrical faults, but, over time, it can degrade due to:

- Ambient and internal heat.

- Overloading.

- Contaminants.

- Poor maintenance.

- Inadequate power quality.

- Mechanical stress.

You may notice cracks or discoloration in insulation during visual inspections. Low insulation resistance readings during testing also indicate potential problems.

Conduct regular insulation resistance testing to detect early signs of deterioration. Protect motors from moisture, dust, and corrosive substances with appropriate enclosures or environmental controls. Managing operating temperatures is also critical for preserving insulation integrity.

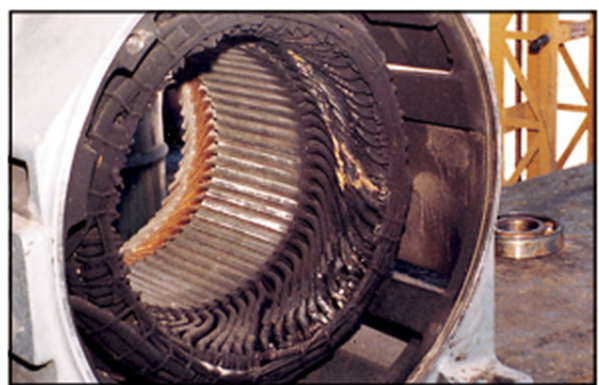

4. Grounded Windings: A Common Hazard

Grounded windings occur when insulation fails due to moisture, contaminants, or physical damage. This creates a direct path to ground, short-circuiting the motor.

Symptoms include:

- Erratic motor operation.

- Difficulty starting.

- Repeated tripping of circuit breakers.

Physical inspection often reveals burned or charred winding ends.

To prevent disruptions in operation and potential damage to the motor itself as well as connected equipment, store spare motors in dry, heated environments to prevent condensation and moisture-related damage. Protect operating motors with appropriate seals to keep out contaminants and regularly test for grounding faults as part of a Condition Based Maintenance program.

5. Phase Imbalance or Single Phasing: Motors Get Stressed, Too

Voltage imbalances or the loss of a phase place unequal stress on motor windings, leading to overheating and failure.

Several issues can cause what we refer to as a “single-phased motor” including:

- Blown fuses.

- Open primary phase at the transformer.

- Unbalanced primary voltage.

- Shunted single-phase loads.

These imbalances manifest as excessive vibration, unusual noise, and uneven heating across the motor. Phase monitors or alarms may frequently trip.

Over time, imbalances cause overheating and wear on specific windings, leading to premature failure. In severe cases, they can damage the motor’s core components.

Use phase monitoring devices to detect and address imbalances early. Conduct routine checks of power supply systems to ensure consistent voltage levels. Maintaining a robust contingency plan for quick repairs or replacements can also minimize downtime.

All Systems Go

In Part 4 o

Electrical failures may seem inevitable, but they are often preventable with the right tools, techniques, and maintenance practices. At HECO, we focus on diagnosing root causes and providing long-term solutions to keep your motors running efficiently.

Contact us to put our expertise and the TracRat system to work in your facility.

Posted in Equipment Management, Repair