Whiskey Straight, No (Sand) Chaser – A Case Study on Optimizing Distillery Water Pumps - HECO

February 22, 2023

Distilling bourbon is serious business, especially in Kentucky. By state law, distilleries must use raw water from the Kentucky River or one of its tributaries in their production process in order for their whiskey to be called Kentucky Straight Bourbon.

For one distillery, collecting water from the Kentucky River is a sandy and fast-paced job. As one of the oldest distilleries in the area, this operation took the “if it’s not broken, don’t fix it” approach to maintenance and repairs for many years. As a result, the operation’s five river water pumps only lasted 3 months between service calls.

When originally installing the pumps and during service calls, HECO suggested a more proactive maintenance program, yet the customer prioritized production over regular upkeep and maintenance.

By working with the pump manufacturer to swap out materials, adjusting machine settings, and convincing the customer to perform minimal maintenance themselves, HECO was able to increase the pumps’ time between replacements by 430%.

The Situation

Manufactured by Goulds Pumps, each of the two-stage, vertical turbine pumps feature a 75 HP motor and are capable of pumping 150 gallons a minute. Hatches in the ceiling of the wooden pump house allow access to the pumps and a movable electric chain lift helps move the pumps in and out of position.

The pumps run long enough to fill up holding tanks or feed into boilers before being shut off. This start-and-stop operation takes place in an area known for its sand and silt deposits, with a sand removal operation just upstream that agitates the riverbed sediments.

The effects of the water composition are further compounded by the customer’s hesitance to pause for preventative maintenance. As a result, the pump caissons did not adequately filter sand, silt, and debris from the water, causing premature damage to pump mechanisms.

Silt and sand accumulated on the bearings and inside the pump.

In addition to silt and sand accumulation, rust also formed on the inside of the line shaft columns.

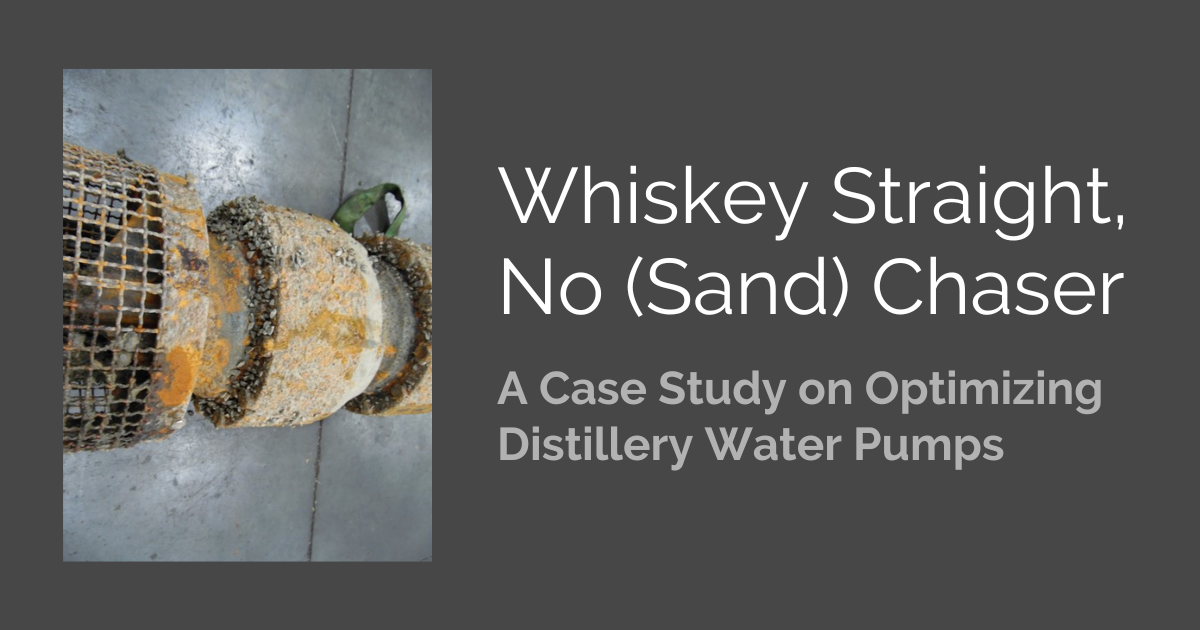

Zebra Mussels also attached themselves to the outside of the pump and made their way through the basket, tearing up the inside of the pumps. The mussels pictured above accumulated in just 3 months of service.

A trash screen, badly in need of replacement, allowed leaves and other debris to clog the pump.

A stick even made its way into the pump and worked itself around until it prevented the pump from spinning, causing the 1 3/16-inch shaft to snap.

A second shaft snapped after a large piece of plastic was sucked into the pump.

One pump was damaged to the point of completely losing its bowl bearing.

The Solution

Working with the pump manufacturer’s engineering team, HECO identified problems with the equipment materials and convinced them to change out the materials used. The original bronze impellers were replaced with stainless steel since the raw water pumpage was eating the bronze.

In the swap, the manufacturer miscalculated the force required to drive the new stainless steel impellers. While the bronze construction in the same diameter required only 75 HP, the new stainless steel version required 143 HP.

HECO removed the pumps and began running its own calculations using the Vesconite bearing calculator. The calculator helped identify the correct clearance and amount of shrink for installation in the housing. It was determined that the diameter of the impellers should be reduced from 9 1/8 inch to 8 7/8 inch.

After a month and a half of its own testing, the manufacturer agreed and made the modifications.

The calculations also recommended cooling the bearings prior to installation. HECO applies dry ice to the bearings for approximately 5 minutes before installation. Otherwise, 800-900 pounds of pressure would be required to force them in.

The new switch from bronze to stainless steel enables the pumps to operate much longer between service calls. Above, at left, the bronze component is shown after 3 months of use. The stainless steel version on the right is shown after 13 months of use.

Despite the presence of sand and small debris, the new pump components show very little signs of wear after serving more than 4 times as long as their bronze counterparts. In fact, the bearings in the second picture were only replaced because the pump had been pulled for preventive maintenance, rather than out of necessity.

Additional improvements include a totally reconditioned and reinstalled pump with a new basket, wear rings, and bearings.

The use of stainless steel provided the distillery with a more durable and efficient pump. The use of Vesconite bearings further increased pump efficiency and wear resistance.

Enabling the mean time between repairs to increase from 3 to 13 months amounted to substantial repair savings for the distillery as well.

After seeing how much more longevity the pumps could gain with proper care, HECO also convinced the customer to clean out their caissons every 6 months. While HECO would prefer a 3-month timeframe for that task, any preventative maintenance is better than nothing.

All Systems Go

Going beyond a service call to work with our customers and manufacturers to determine the best components and develop plans of action is important to the HECO team.

Since our founding in 1959, HECO has provided expert repairs and Predictive maintenance to electric motor systems, pumps, and rotating equipment in a variety of industries. To learn how we can help your facility run smoothly with dependable motors, pumps, and other equipment, contact us.

Posted in Field Service