Importance of Air Gap in Electric Motors

May 19, 2020

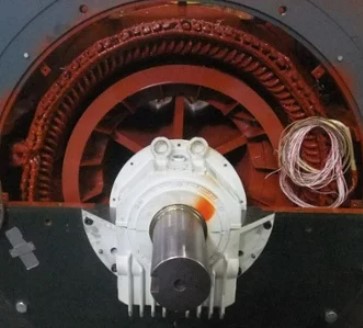

The air gap refers to an actual physical gap in an electric motor that separates the moving rotor and the stator core. This gap is a necessary part of motor design and the size of the air gap is one of the keys to motor performance and reliabilit.

The Case for a Correct Air Gap

The air gap needs to be large enough to prevent contact between the rotor and stator, taking into account tolerances related to their respective dimensions, loose bearings, and movement that results from deflection during operation. In addition, if the rotor is eccentric relative to the stator and the air gap is too small, the stiffness of the shaft might be overcome by the resulting unbalanced magnetic pull. This, in turn, leads to damage resulting from the rotor striking the stator as it is pulled out of place by the magnetic forces.

At the same time, the motor’s air gap needs to be as small as possible because wider air gaps require more power to achieve magnetization. In short, in air gap that is wider than necessary could have a negative impact on the efficiency and performance of your motor.

Air Gap Eccentricity

We just talked about how important it is for the air gap to be the right size — it is also extremely important that the air gap be uniform. When the air gap is eccentric, the motor is going to vibrate and make noise. While noise in and of itself is not a big deal, it is important to realize that both noise and vibration (relying on vibration analysis) reduce motor performance and can lead to components wearing out faster than normal. This leads to higher M&O costs and more downtime.

But noise and vibration aren’t the only issues with an eccentric air gap. It can also lead to increased coil movement which can speed up how fast the coil insulation degrades. If the eccentricity is large rough, the magnetic pull can become unbalanced and lead to rubbing between the rotor and stator, which is never a good thing.

So how is a uniform gap defined? Obviously, perfect uniformity is ideal but not very realistic. Most motor design and repair professionals recommend that air gap variation should never exceed +/- 10% of the average air gap.

Causes of Air Gap Issues

So, what causes air gap in electric motors? There can be a variety of underlying causes, including obvious ones like a bent shaft, cocked bearings, or out-of-roundness of either the rotor or stator during manufacturing. Other causes can include incorrect mounting of the motor to the bedplate, or drive belts that aren’t properly tensioned, or even a bowed rotor.

Testing for Air Gap Issues

There are three methods that can be used to reveal the presence of an air gap: MCA (Motor Circuit Analysis), CSA (Current Circuit Analysis), and RIC (Rotor Influence Check). While they can point to an air gap, they cannot always reveal if it is getting worse over time and how much eccentricity is actually present.

Air gap size and uniformity is bigger issue with large motors and large motor repair.

Conclusion

Electric motor air gaps can have a tremendous effect on motor performance, whether the gap is too big or too small even more complications arise when the air gap is eccentric. And to make matters worse, it can be an even bigger problem for large motors. In short, if you are having motor performance issues as described in this article, consider air gaps!

Posted in Equipment Management