How Much Does Predictive Maintenance Cost?

October 16, 2024

In theory, Predictive maintenance is the best option for every industrial facility.

Monitoring in-service equipment allows you to forecast when repairs will be needed rather than waiting for a failure to occur before intervening (run-to-failure approach) or performing work based on time used rather than actual needs (time-based maintenance). The actionable insights gained are specific to each piece of equipment and ensure the highest level of productivity.

In practice, however, maintenance managers often wonder which version of this customized and proactive approach is best, how much it will cost, if it is the right method for their applications, and how to justify the costs to C-suite decision-makers.

Many times, the deciding factor comes down to cost. So, how much does Predictive maintenance cost?

The answer depends on your application and expectations and is relative to the cost of failure for your equipment. Understanding the various approaches to maintenance as well as your related costs and expectations is the best place to start.

HECO understands that each facility and even specific systems within them have unique thresholds when it comes to Predictive maintenance. Here are some key points to consider when evaluating your maintenance needs and the need for Predictive maintenance.

Criticality and Costs

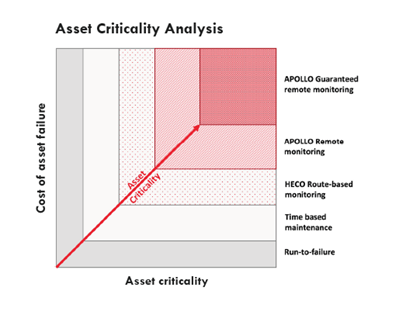

The first step in considering a Predictive program is to analyze each piece of equipment in your facility through the lens of this graph. Once you do that, you’ll get an idea of the costs of a Predictive program for your needs and goals.

The maintenance approach for each piece of equipment differs. The type of maintenance and investment needed for an asset increases with its criticality and the cost of its failure.

Costs will also differ for each facility because of all the unique assortments of equipment and applications considered in the asset criticality analysis.

Your ideal maintenance approach depends on asset criticality and the cost of asset failure and repair. The more expensive a failure would be in terms of the cost to repair or replace equipment and the associated downtime, the more high-touch and expensive the maintenance program needs to be.

Maintenance Strategies

At HECO, there are five different approaches to maintenance we recommend based on the results of your asset criticality analysis. Of these approaches, three are Predictive in nature, but not necessarily the right option for all equipment.

Run-to-Failure

Think of this as firefighter maintenance. You’re only taking action when there is an emergency and putting out fires.

This is not necessarily a bad thing, especially if the equipment in question can be quickly and cost-effectively replaced, as long as there is a plan to take this approach before an issue occurs.

Time-Based Maintenance

This preventative approach mitigates failure by changing parts out on a regular basis. Actions are scheduled and less predictive. Monitoring is performed at predefined intervals rather than from a technological standpoint.

Similar to getting the oil and filter in your vehicle changed every three months regardless of their condition, this approach does not incorporate conditional triggers.

Route-Based Maintenance

Similar to time-based approaches, route-based maintenance is performed at predetermined intervals but it also utilizes technology to identify issues before a problem occurs, making it a Predictive method of maintenance.

With this approach, a technician evaluates and monitors equipment as part of a set routine. Measurements and tests of equipment are taken at specific intervals, for example once a month, to look for issues and create a pattern of operation over time. A human then analyzes the collected data.

The frequency of the routes is tied to an equipment’s criticality to production.

Remote Monitoring

Using technology, remote condition monitoring allows you to have eyes on your equipment at all times. HECO offers APOLLO as its remote condition monitoring service. Remote sensors collect data and send it to the cloud for machine and human interpretation.

While more of an investment than the three maintenance approaches already discussed, this method is the best at predicting potential failures because of the constant monitoring and automated analysis. APOLLO takes the data from sensors and uses machine learning to understand your equipment’s data and what signs to look for that tell the HECO engineers a failure is upcoming.

As a result, less unexpected downtime occurs, and your team is more aware of machine conditions and needs.

Guaranteed Remote Monitoring

Taking remote monitoring one step further in terms of its reach and cost, guaranteed remote monitoring is the most intensive form of Predictive maintenance.

With this approach, the company who oversees your remote condition monitoring makes a financial guarantee to you they will cover some or all the cost of your repairs and downtime if they and their sensors miss something resulting in an issue.

HECO’s APOLLO has this option and is ideal for your most critical and costly to repair and replace systems.

All Systems Go

No matter which maintenance approach you take, it’s important to have a plan in place and set your expectations before an issue occurs, especially with your most critical pieces of equipment. Understanding which Predictive maintenance strategies you should use for each piece of equipment will go a long way towards helping you understand how much a Predictive maintenance program should cost.

HECO can help you determine which approach is best suited for your needs and apply the most fitting approach to each specific equipment’s criticality and cost benefits.

Contact us to discuss your need for Predictive maintenance and help in keeping your electric motors running with maximum reliability.

Posted in Predictive