How Does Vibration Analysis Work?

May 8, 2019

In recent years, companies have entered the transition from reactive maintenance, to planned maintenance, and into the most efficient method found in predictive maintenance. While the first two methods have dominated in the past, they have been found to be costly, inefficient in time, and sometimes result in over-maintenance of machines.

In predictive maintenance, machine downtime, cost for spare parts, and overtime are all held to a minimum. With all of these benefits, you may be asking – “What is the best implementation of predictive maintenance in my workplace?”

One of the most effective ways of predictive services is Vibration Analysis.

What is Vibration?

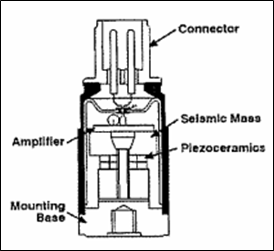

Vibration Analysis is defined as the measurement of movement of a point on a machine. In order to measure the vibration (motion) of the point on a machine, you would use a vibration sensor. This transforms mechanical motion into an electrical voltage, which is generated by the compression of a piezoelectric crystal inside the sensor. This electrical signal is then sent to the vibration analyzer connected to it.

The most common vibration sensor used today is the industrial accelerometer (a basic breakdown of an industrial accelerometer is pictured on the right).

How Vibration Analysis Works

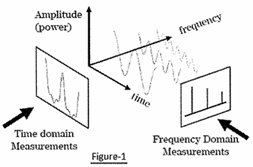

After taking a measurement with a vibration analyzer when the sensor is mounted to the machine, the analyzer will read the incoming electrical voltage generated by the piezoelectric crystal and generate what is known as a Time Waveform (time domain). This plot compares the amplitude of vibration versus time.

Most vibration analyzers will transform the Time Waveform into a Frequency Spectrum (frequency domain) using an FFT (Fast Fourier Transform) process. The Frequency Spectrum plots vibration amplitude versus frequency. This allows the user to detect a much wider range of machinery faults than the Time Waveform is capable of.

Common Vibration Analysis Detections

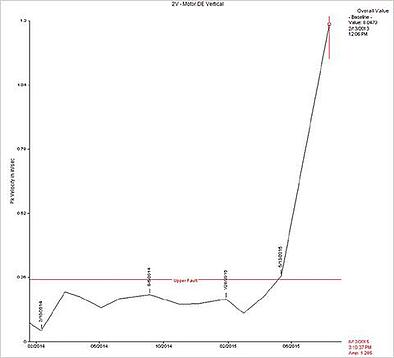

There are a variety of things that you can detect when analyzing vibration data, especially with frequency spectra. Some of the common faults that you can find are looseness, imbalance, misalignment, bearing faults, belt problems, and many more.

With such a wide range of problems that can occur, you also may ask – “How do I differentiate between all of these possibilities?”

A few basic ideas that distinguish these faults from one another include synchronicity to machine running speed, the frequency range at which the peaks occur in the spectra, which peaks are present and which are not, etc. Being able to accurately diagnose these machinery problems requires many hours of training and practice, but can lengthen the life of your motor once detected.

Posted in Predictive