Visual Inspections are still as important as ever!

February 22, 2017

In the world of technology, more specifically maintenance technology, there are so many different tools we are using to make decisions. We use vibration analysis, ultrasonic analysis, motor current analysis, thermography, and so many other technologies that many times the most simple and cost-affordable technology is sometimes forgotten: YOUR EYES!

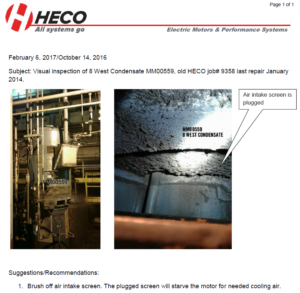

Visual inspections can tell you a lot about how a piece of equipment is running. Does it have clogged filters? is there an oil leak? is the oil level high? is it low? Is the fan cover plugged? are cooling fins plugged?

Most plants have some form of visual inspections that people from operators to maintenance are performing. Sometimes they are daily and sometimes they are quarterly. Does you plant have a defined set of items they are reviewing on each component? Or are they just walking around looking for obvious items? Have they been trained?

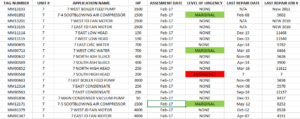

We perform some visual assessment programs for our customers and we treat this just like we do a predictive maintenance route. We provide a color-coded report on all items and then a more detailed report with images of any item that has an anomaly. It’s amazing what simple pictures can do in showing what the issues are. Here are some examples of the larger report as well as a detailed individual report.

As you can see there are easy items that you can review and look at to help prevent equipment problems in the future. Just don’t toss aside visual inspections for the sake of newer, “more cool” technologies!

Posted in Predictive