Specialty Equipment Repair

HECO offers custom repair solutions for unique and specialized industrial equipment. Whether it’s custom-built machinery, rotating equipment, or non-standard motor systems, our team applies decades of expertise to diagnose and restore function to keep your critical assets in peak condition.

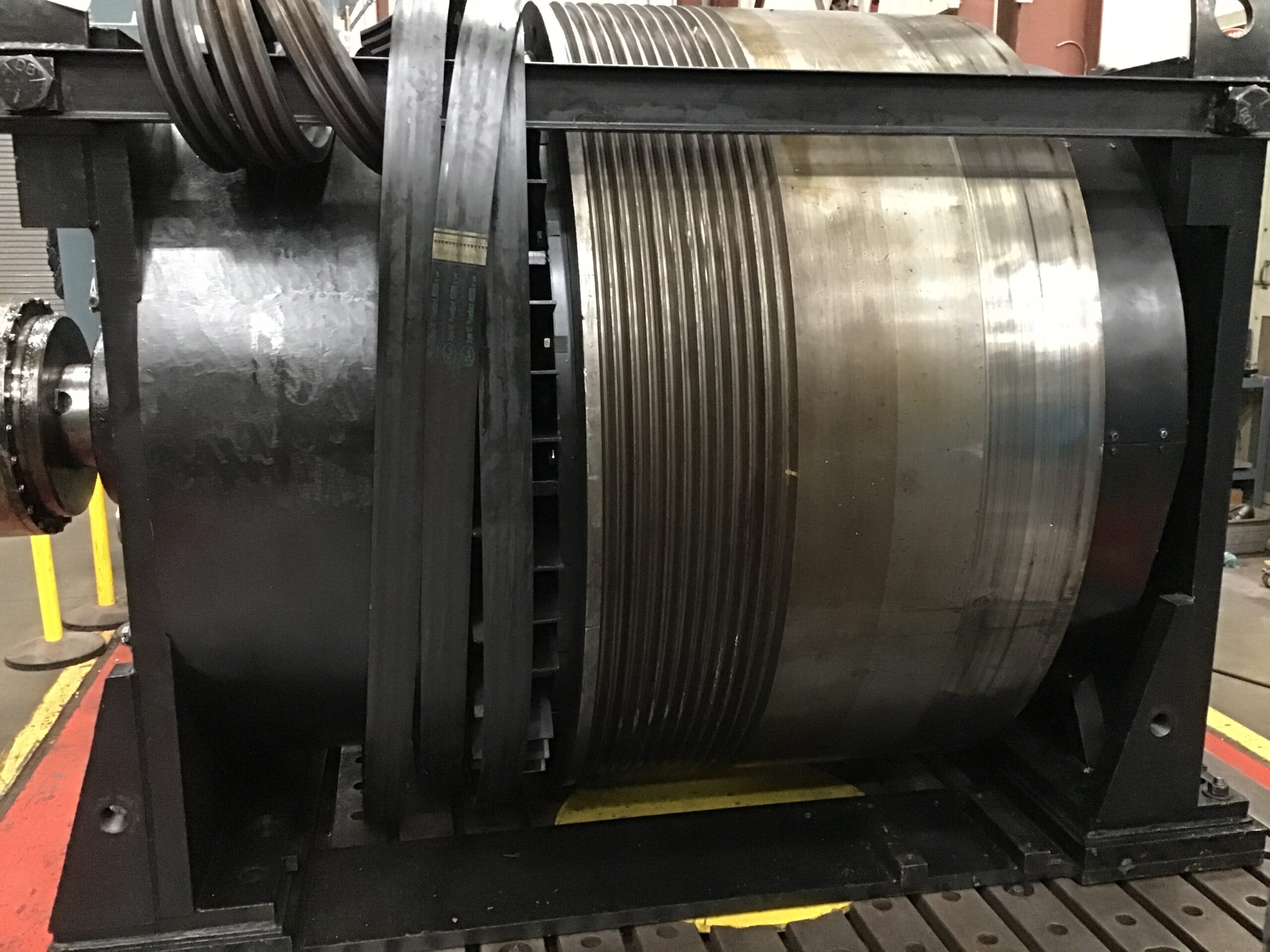

Eddy Current Clutch/Drives

- Full disassembly and inspection

- Clutch coil repairs and rewindings

- Bearing replacements

- Machining and alignment

- Rotor and drum refurbishment

- Seal and gasket replacement

- Testing and calibration

- Unit restoration

- AC induction motor support

Servo Motor Repair

- Full disassembly and inspection

- Electrical and mechanical component testing

- Component cleaning

- Bearing changes

- Rewinding

- Final testing

Liquid Rheostat Repair

- Tank repair and replacement

- Electrode reverse engineering and replacement manufacturing

- Heat exchanger service and upgrades

- Carriage repair and alignment

- Bushing replacement

- Electrode drive motor repair and replacement

- Tank cleaning and corrosion prevention

- PLC repair and calibration

- Sensor calibration and testing

- Bearing and seal replacement

- On-site repairs

- Custom liquid rheostat manufacturing

- AC induction wound rotor/slip ring motor repair

How a HECO Repair is Different

The way we think is what makes us and our repairs different. You’ll experience it with the first job when we ask you a variety of questions, such as:

- Why are you removing the unit? Did it fail?

- What is the application for your unit?

- How long has the unit been in service?

- What type of starting is used?

- Are there any special instructions?

Using these questions as a means to uncover the “why” of any issue you are having, HECO then focuses on potential issues to make the right repair on the first service and prevent the need for recurring repairs.

Learn more about how a HECO Repair is different.

Take A Virtual Tour

Want to see what kind of shop your motors will be going to? Check out a virtual tour of our Kalamazoo location.