Protect Your Equipment with Skyler Rotate’s AI-Powered Insights

Posted on 04/02/2025.

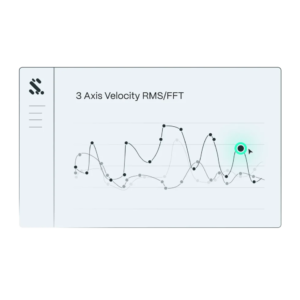

Change is an essential part of innovation. At HECO, we are committed to providing cutting-edge solutions that drive reliability and efficiency. That’s why we’re excited to introduce Skyler Rotate, the …