Steel & Other Metals

Specific Solutions Built Around Steel & Other Metals’ Unique Needs

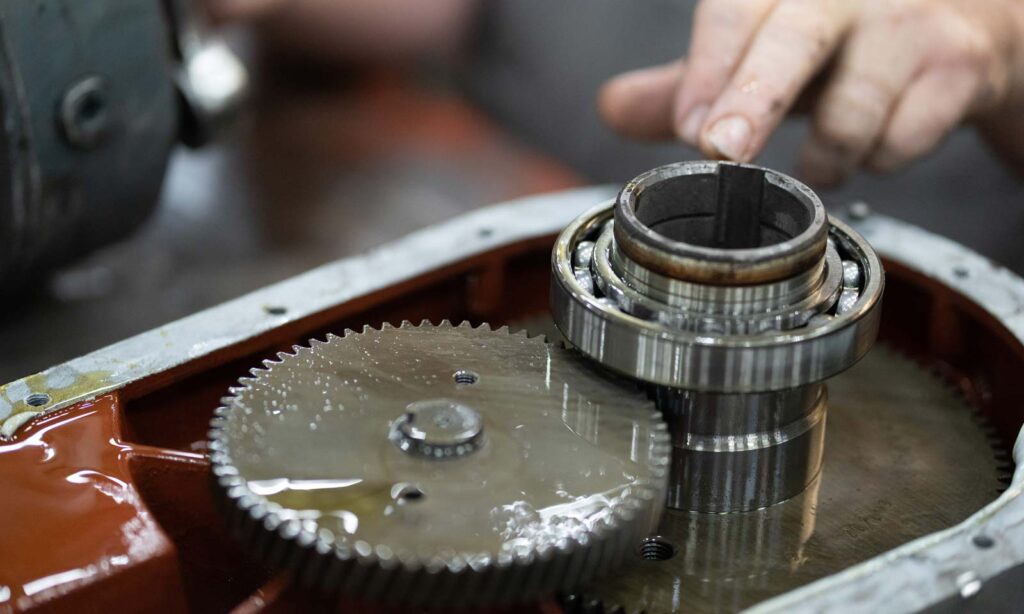

HECO is currently doing everything from repairing drive motors to vibration analysis to performing PdM on all rotating equipment for steel mills across the United States.

These steel mills choose HECO because they know we understand the challenges of electric motor repair in the steel industry. Electric motors in steel mills face some of the harshest environments imaginable, and unexpected failure can cost mills tens to hundreds of thousands of dollars or more in downtime.

At HECO, we strive to reduce your downtime by:

- Providing quality repairs

- Supplying you with the correct electric motor for your application

- Ensuring that spares are functional and readily available

Our approach to managing complete electric motor driven powertrains has been proven at some of the largest steel mills in the country and with some of the largest electric motors.

HECO also provides a Unit Exchange Program for electric motors designed specifically for the steel industry.

We repair, replace, and manage:

- Cold Strip Mill Motors

- Main Drive Motors

- Main Drive Generators

- Coiler Motors

- Finishing Mill Motors

- Large Drive Armatures

- Compressors

- Fans

- Cranes

- Mill Duty Motors

- Blowers

- Generators and Excitation Units

- Roll Grinders

- Pump House Motors

- Tin Mill Motors

- Runout Table Motors & Unit Exchange Programs

- Stack Fans & Unit Exchange Programs

- Other AC & DC Motors

- Foundries

- Muellers

- Mixers

- Shakers/Vibratory Motors

- Air Compressors

- Joy Compressors/Synchronous Compressors

- Pollution Fans

- Bag Houses/Dust Collectors

- Scrubbers

- Fans

- Mining

- Draglines

- Shovels

- Generators

- Drilling Motors

- Conveyors

- Cranes

- Compressors

- Crushers (Primary & Secondary)

- Loaders

- Pumps

- Other AC & DC Motors

- Aluminum, Scrap & Other Metals

- Shredders

- Cranes

- Extruders

- Briquetters

- Compressors

- Generators

- Other AC & DC Motors

Take Advantage of Our Resource Library

Download a Free E-book Today!

Our E-books provide tips and describe steps to take that will help you minimize downtime and keep your plant running.

- What to Look for in an Electric Motor Repair Shop

- How to Get the Right Electric Motor

- Reliability Maintenance is Good Medicine

- Electric Motor Field Service: Is It Right for Your Facility?

- NEMA Electric Motor Frame Standards